Then, last week, out of the blue, a friend rang up to invite me for a day on the Tweed in early March. Despite less than fond memories of last year's snow, freezing easterly wind and falling in, I accepted with alacrity verging on indecent haste, supported by appropriate gratitude. Once I'd got over the excitement the reality set in. With 3 weeks to go - one of those lost to a business trip to the Gulf; the other 2 obstructed by more routine work; and a major backlog of weekend gardening - I needed to get my fishing brain back up to its normal pace and sort myself out. As I'm an orderly person, sorting out my kit is fairly straightforward. Rods and wading kit are all together at one end of the loft. Everything else is in the Great Fishing Chest that lives at the top of the stairs.

|

| The Great Fishing Chest |

|

| GFC with 3 layers in view Trout reels and flies above, salmon below |

|

| GFC - Bottom Layer |

|

| GFC - Middle Left Layer |

This shelf contains the entirety of my business-end salmon kit - flies, tubes, polyleaders and tippet material. The blue box is labelled 'Low' (water), the red 'High': it's that simple. The big clear tube box lives in the car pack and feeds the Snowbee mini-box as necessary. Four patterns of tubes predominate: Black & Yellow (early season); Cascade; Shrimp; and Sunray Shadow.

This week's immediate challenges lie in checking, purchasing and delivery. Identifying the small gaps in the inventory and producing the shopping list is quick and pleasurable. John Norris is very efficient, but there's a lead time to delivery. Then there's stuff that needs fixing. Fortunately the list isn't extensive and in January I'd sent my waders off to Diver Dave for their annual service and re-proof (£35 very well spent); and re-proofed the wading jacket with its shooting cousin's end of season wash (Nikwax Goretex Wash & Re-Proofer). Nevertheless I still need to:

- Get the life jacket off for servicing (Diver Dave again)(done).

- Replace the studs the wading boots shed in September and October. That will have to wait until I get back from UAE. There are 2 things to bear in mind. The ultra-hard and more expensive studs are good, but unless your boots have specific studding points, screw-in studs tend to fall out before they wear out, so I just buy standard items. US manufactured studs are 1/4 inch, whereas European are 6 mm, which handily fit the hex-drive socket in my electric drill. This reduces re-studding time to 5 minutes with the wading boot clamped in the Workmate.

- Replace the worn laces in the wading boots before they break on the first day of the season. I'd bought a pair and a spare, only to find that I'd picked up the wrong length. With all the eyes wading boots generally need a 64-72 inch lace (yes, I know that sounds enormous). I always keep a spare pair in the transit box - which I needed on the last day of last season) and so has to be replaced.

- Buy new fluorocarbon tippet material: Seaguar 19 lbs for springers and 15 lbs for the rest of the season. It's expensive but safer to ditch last year's spools, especially if you don't wish to be ridiculed by a Tweed ghillie doing his party trick of snapping your tippet with disdainful ease (which tempts me to pop a spool of pike wire into the box to catch him out).

- Check my stock of polyleaders (I've used Airflo for years and found them as good as any) and order replacements as necessary.

- Go through the fly boxes to ascertain the gaps. The bent, broken and worn out went in the bin at the end of the season. Now I need to fill the gaps, mostly larger Cascade doubles and a couple of black and yellow tubes. The reasoning behind black and yellow as an early season fly is given in last year's Here's Looking at You post.

- Replace the mesh on my trusty old Gye net with the new one obtained last month by phone from Snowbee in Plymouth (£14).

- Check and if necessary replace the magic elastic that operates my folding wading stick. It's been working for years, albeit getting a bit softer with each passing season (bit like its owner), but it won't last for ever, and I'd sooner fix it in the workshop than have to do some kind of bodge-fix on the riverbank.

- Wash and polish the lines (see The Countdown for method)

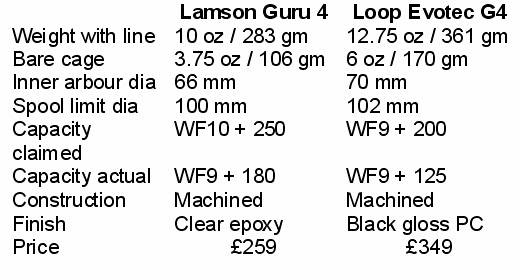

- Check the reels to make sure nothing got stuck during the winter stowage (despite the end of season servicing). The unreeling and re-winding of the line cleaning process takes care of this.